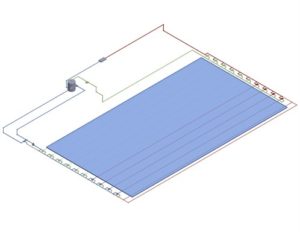

A demonstration of a variable heat rejection radiator technology was carried out at the Interphase Transport Phenomena Laboratory (ITP) at Texas A&M University (TAMU). The technology utilizes a vortex type separator and a passive educator/jet pump to exchange working fluid in the radiator segments/lines with a non-condensable gas located in the phase separator. The Figure below is an illustration of the proposed system that is based on variable heat rejection studies in the literature and includes a phase separator and eductor. The system shown here illustrates the warm liquid (in red) entering the radiator and being cooled (cool liquid shown in blue) returning to the pump and phase separator. Non-condensable gas shown in green can be used to displace liquid in the radiator based on the orientation of 3-way latch valves located at the entrance and exit of either a single radiator line or a manifold of lines. By actuating the valves, gas and liquid can be exchanged between the separator and radiator which can control the area of radiator available for thermal energy rejection.

Component and system level experiments were carried out and modeling was completed for use in the sizing of separator and eductor components for a given radiator line volume to be evacuated. Tests were carried out to show the integration of a passive eductor pump with a phase separator could be used to clear lines and vary heat rejection. A bath type heat exchanger was used rather than a radiator. A review of various instrumentation methods was also performed and is mentioned in the report. Results show that the technology can successfully perform variable heat rejection by repeated evacuation and filling of selected pipe sections used to simulate single phase radiator line segments.